Repair and Adjustment Bridgeport Power Quill Feed

- #1

hey guys, got a 1974 BP 2J 1.5hp. mill, it is my understanding the power quill feed should stay engaged until the micrometer nut bottoms out right? my lever springs back immediately which is especially dangerous because the clock spring on opposit side of head is broken/damaged in some way so the quill thumps all the way down if you let go of the feed lever.

my question is, is there an adjustment for this or is it working properly?

also, is there rh or lh threads on the large slotted head center screw retaining rh quill handle shaft/bushing assy. (to access clock spring i assume)

-which i shoud really fix before i hurt myself

one more for ya- the factory preset power quill downfeed pressure clutch seems awful light? can make it trip quite easily. anyone adjusted this themselves or dangerous territory? sorry for all the rambling but if anyone knows you guys will! thanks much for any info.

- #2

hey guys, got a 1974 BP 2J 1.5hp. mill, it is my understanding the power quill feed should stay engaged until the micrometer nut bottoms out right? Yes

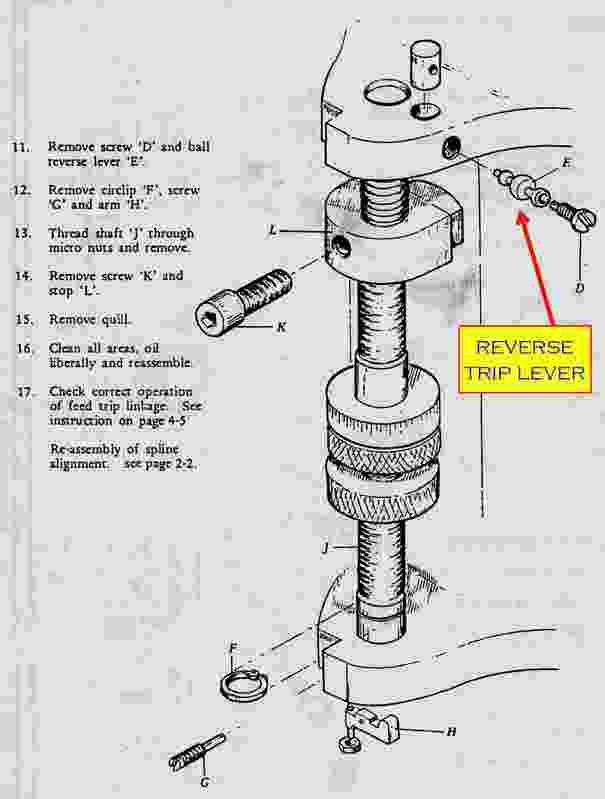

You also need to look at the reverse trip lever to make sure it is not broken.

my lever springs back immediately which is especially dangerous because the clock spring on opposit side of head is broken/damaged in some way so the quill thumps all the way down if you let go of the feed lever.

my question is, is there an adjustment for this or is it working properly? You need to replace the clock spring.also, is there rh or lh threads on the large slotted head center screw retaining rh quill handle shaft/bushing assy. (to access clock spring i assume) Right hand thread.

-which i shoud really fix before i hurt myself

one more for ya- the factory preset power quill downfeed pressure clutch seems awful light? can make it trip quite easily. anyone adjusted this themselves or dangerous territory? It was adjusted at the factory. It can be adjusted by you if you follow the procedures. Let me see what I can find and attach it below.

sorry for all the rambling but if anyone knows you guys will! thanks much for any info.

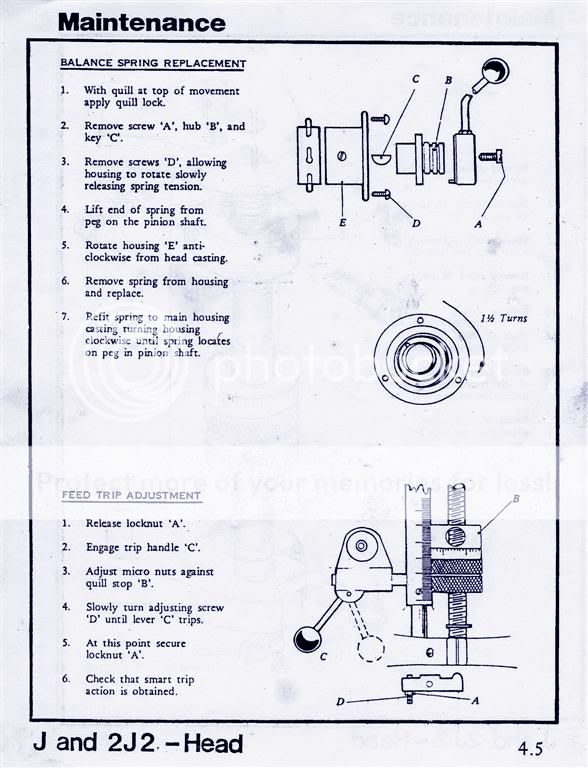

To replace the clock spring, follow these instructions....... Here is After you have checked the condition of the trip lever, replace it if found broken and then go back up to 4.5 and set the adjustment.

If this breaks the downfeed will not work. The trip lever is easily broken in the middle, I guess because of it's shape........

This should make your quill feed work again. It will advance the quill downward until it reaches the nut (about .010 before actually) and then kick out the lever.

This works like that either going up or going down........pg

PS....... I did not find the procedure describing the clutch adjustment but if you still want it let me know. I have it around here somewhere.

- #3

I would like to see the clutch adjustment procedure please. My power feed works fine when taking light cuts in Delrin, so I don't think that anything is broken. But when trying to drill a 1/2" hole in mild steel, it keeps tripping out. I know the power feed is not intended to be used for heavy drilling, but is a 1/2" hole excessive?

- #4

I would like to see the clutch adjustment procedure please. My power feed works fine when taking light cuts in Delrin, so I don't think that anything is broken. But when trying to drill a 1/2" hole in mild steel, it keeps tripping out. I know the power feed is not intended to be used for heavy drilling, but is a 1/2" hole excessive?

Yes it is excessive and most likely that is your problem. The overload clutch is set at the factory to hold up to 200 lbs of down pressure on the quill, which will accommodate drills up to 3/8 inch diameter drilling mild steel. Larger than 3/8 drills require manual operation. This is followed by the note......."CAUTION- This clutch should not be tampered with in the field" One of my older manuals gave the instruction for adjusting the overload clutch but I am unable to lay my hands on it now.

Since you are exceeding what the machine was designed for I suggest you just use manual opps with the half inch drill........... pg

- #5

The clutch and power down mechanism on a BP is designed for about 200 pounds of thrust/ (down pressure).

that's a 3/8th drill in mild steel.

CalG

(Believe what PG says, his font is bigger ;-)

Last edited:

- #6

Thanks guys. I'm relieved to learn that my machine is doing all that it is intended too, and a little emarrassed that I was asking it for more.

- #7

DustyU

When you get a new clock spring order up the two pins it hooks onto as well. Very little extra money to avoid endless frustration if the existing pins are worn or damaged just enough that the new spring won't hook on or, worse, comes off after about ten ups-downseys. Can be made but, like so many small items, the effort is out of all proportion to the savings, especially when your temper is fizzing near the Danger UXB line.

Its also worth making yourself a little pin spanner affair to engage in two of the screw holes in the cover so you can turn it easily for the 1 1/2 turn wind up and keep it under control whilst putting a screw in.

Its easy to slip a new spring in with the control wire still on it. Once its in and the wire slid off it fights back hard!

Clive

- #8

thanks Piniongear for all the great info and schematics. took a look at my mill tonigt and was surprised to see part "H and G" completely missing! also it looks like someone replaced part " D and E" with a hex set screw? somenone has meen meddling something fierce here! got looking at it and if i pull the shaft operated by the MIA part "H" down, the feed engagement lever stays engaged as it is supposed to and trips fine when pushed upwards. looks to me all i need is every single part in the diagram. gee that should only be about $300 worth of giblets. any suggestions where i should order these?

i have a High Quality Tools inc. replacement parts catalog-anyone had good business with them?

- #9

thanks Piniongear for all the great info and schematics. took a look at my mill tonigt and was surprised to see part "H and G" completely missing! also it looks like someone replaced part " D and E" with a hex set screw? somenone has meen meddling something fierce here! got looking at it and if i pull the shaft operated by the MIA part "H" down, the feed engagement lever stays engaged as it is supposed to and trips fine when pushed upwards. looks to me all i need is every single part in the diagram. gee that should only be about $300 worth of giblets. any suggestions where i should order these?

i have a High Quality Tools inc. replacement parts catalog-anyone had good business with them?

DustyU........ Go to the website by using the link. It is a bit difficult to locate the stuff you are trying to find, but once you get the hang of it, the search is easier. Move the cursor over the different parts and a descriptive title will pop up. Click on the part and a very good photo and the price of the item will be shown. Click the back button to return to the display. That's how it works. To help you get started, the parts you need items (D & E) are going to be items #67, 68, & 69 in ICAI's display. The items for (G & H) are going to be #73, 74. & 75 on the display. Of course some of these parts, if not all, could be made. I think it more cost effective to just pay the piper and buy the parts myself since you do not have a pattern to go by. The clock spring is shown in the display also, but I thought it would be easy for you to spot. You can add up the $$ for these parts too.

Looks like you found your problem. You can get the parts here..........

http://www.icai-online.com/home.php

Like everything, the stuff is expensive, of course. If it makes you feel any better take the trip reverse ball as an example..... these guys sell it for $22.36

I paid a local supplier $32 for the same part 2 years back.

I have heard another member here bought one for $18.

So, you may want to shop around some?

Click on

This takes you to another selection window...... click on 'Quill Housing Assembly'

This gives you a large display of all the parts involved with the quill.

Everything totals up to about $76.99.

Good luck with it and let us know how it turns out............ pg

Source: https://www.practicalmachinist.com/vb/bridgeport-and-hardinge-mills-and-lathes/power-quill-feed-doesnt-stay-engaged-175086/

0 Response to "Repair and Adjustment Bridgeport Power Quill Feed"

Post a Comment